Successful inventory tracking does not come without its challenges, but having the right tools in place can help you scale and save money. ShipBob is a great solution for fast-growing online brands that need to scale their ecommerce shipping and logistics. Merchant A clearly has a much more accurate way to track inventory than Merchant B. Lean Six Sigma combines the Six Sigma methodology with lean manufacturing to increase efficiencies within your inventory management process. For example, you may use it to streamline your process by eliminating unnecessary steps. However, the consignee has to cover any holding costs and is responsible for selling the products, which means they can lose money if they don’t sell.

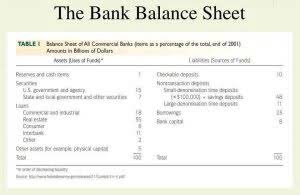

At the same time, inventory can be thought of as a liability (if not in an accounting sense). A large inventory carries the risk of spoilage, theft, damage, or shifts in demand. Inventory must be insured, and if it is not sold in time it may have to be disposed of at clearance prices—or simply destroyed. Having visibility into the timing and location of stock arrivals enables better management of distribution centers and warehouse logistics, such as receiving and put-away tasks. That’s because audits offer important insights into where your inventory is located, and whether certain SKUs have been misplaced or mispicked (which gives you a chance to correct these problems, if needed). Integrating a 3PL into your existing processes can streamline many facets of it.

Methods of Inventory Tracking

Having a place for everything and everything in its place makes all of your inventory-related tasks quick and efficient. If you handle inventory in your own facility or store, first organize and identify storage areas, such as racks, shelves and bins, then assign each product to a specific area. Here’s a seven-step approach to creating an inventory management plan with procedures, controls and tools tailored to your business’s unique needs. The good thing about the spreadsheets is you can set formulas, color codes, and pump out reports and charts based on your spreadsheets.

- For more information on how Sage uses and looks after your personal data and the data protection rights you have, please read our Privacy Policy.

- While it may be a cost-effective option for small businesses with limited inventory, it is prone to human errors.

- Are you looking to know more about inventory tracking and what it can do for you?

- Knowing the ACV can guide your inventory strategy, from storage to ordering policies.

- It’s essential if you want the right mix of products available to sell to your customers.

- It’s used in inventory and supply chain management to reduce excess and obsolete inventory write-offs.

Inventory is only an asset until it’s sold, then it becomes a “cost of goods sold” (COGS) expense. Asset tracking accounts for the cost and depreciation of the equipment and supplies that a business purchases to operate. Plus, they seamlessly connect sales channels and fulfillment sources within one system, so you’re primed for growth. How you source and store the various products you sell determines how you manage your inventory. If you stock all products in your own facility, your inventory controls and processes are handled internally.

Solving Inventory Tracking Challenges

This is because there is much less manual work involved and your system will be in charge of monitoring your stock and keeping your data updated. This can ensure you always have an updated inventory, which helps you keep a sufficient amount in stock to fulfill orders and avoid running out. Reorder points represent the inventory levels at which new orders should inventory tracking methods be placed. Reorder points are specific to individual inventory items and are based on that item’s average daily usage, order lead time and the amount of safety stock you have on hand. Reorder points are an essential part of inventory management and help you avoid stockouts. Thrive by Shopventory is another excellent Shopify app for inventory management.

Recent Comments